NEO-BD Precision Assembly Winder

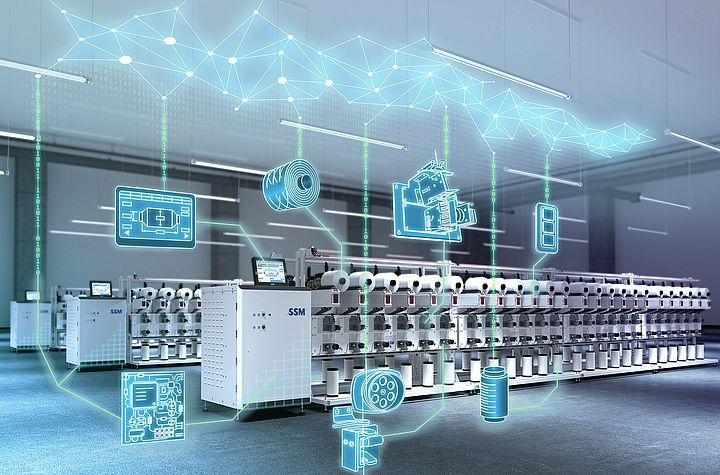

SSM unveils the NEO-BD precision assembly winder — a next-generation solution that pushes the boundaries of speed, quality, and consistency in yarn production.

Modern textile manufacturing demands both precision and productivity, and the NEO-BD delivers on both fronts. Designed with Swiss engineering excellence, it combines innovative control systems with gentle yarn handling to redefine efficiency in assembly winding.

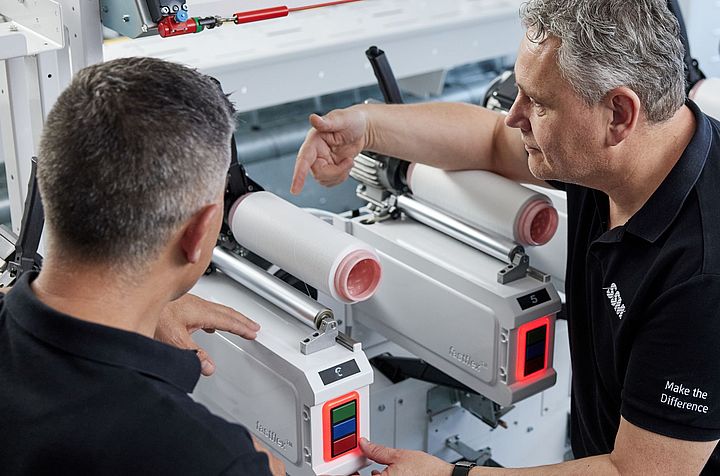

Smart Engineering for Faster, Gentler Winding

The NEO-BD reaches production speeds of up to 1 600 meters per minute while maintaining exceptional yarn quality. Its unique counter-rotating blade system — nearly free of wear and tear — minimizes yarn tension and mechanical stress. This results in smoother processing, lower operating costs, and longer equipment life.

Advanced Technology for Unmatched Control

The NEO-BD integrates several intelligent systems that ensure perfect winding precision:

- preciforce: continuously adjusts back-pressure force to maintain uniform package density with pinpoint accuracy.

- digitens: provides real-time tension monitoring to ensure consistent yarn tension across every spindle.

- Precision length measurement: controls package weight within a margin of ±0.3%, optimizing downstream performance and reducing waste.

Together, these systems guarantee consistently compact, high-density packages — ideal for twisting operations that benefit from smaller balloon sizes and reduced energy use.

Success story

Discover how Hebei Jingze Textile Ltd. doubled their production capacity while achieving 5-10% quality improvements using NEO-BD.

Setting a New Industry Standard

With its combination of precision control, consistent performance, and energy efficiency, the NEO-BD sets a new benchmark for high-speed winding. It enables textile manufacturers to achieve higher throughput without compromising quality — a decisive step toward more efficient, sustainable production.