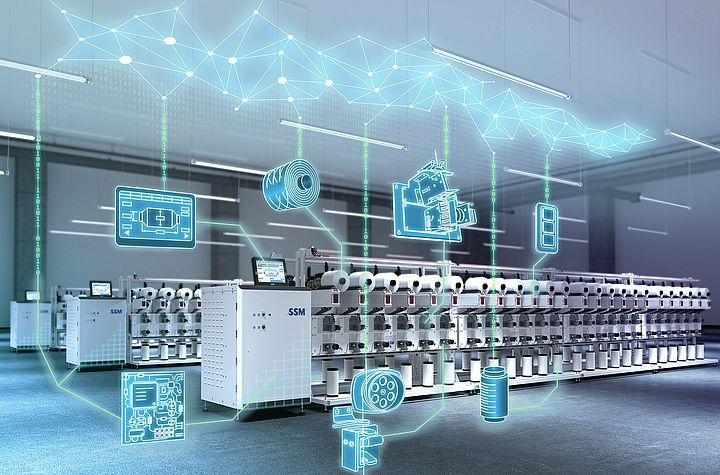

Hebei Jingze Textile Co., Ltd. — a leading sewing thread producer in China — has set a new benchmark for precision winding by integrating SSM’s NEO-BD precision assembly winder into its operations. With this step, the company achieved a 100 % speed increase, higher yarn quality, and greater process reliability — all while meeting rising customer demands for consistency and performance.