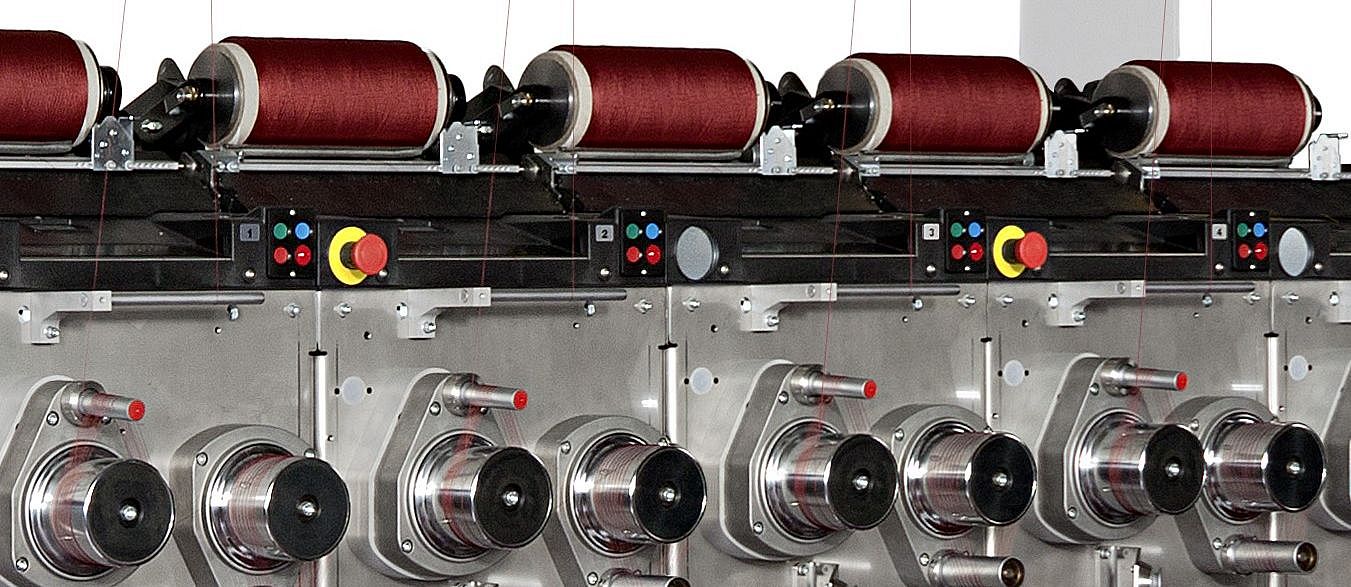

With the DP5-S-line, SSM offers a flexible and energy efficient draw winding machine, which permits the cost-effective production of high-quality fully drawn yarns or twisted technical filament yarns such as sewing threads.

Draw Winding Machines

DP5-S POY

The DP5-S POY is designed for draw winding of all types of POY (PES, PA and PP). The flexible and energy efficient machine permits the cost-effective production of high quality fully drawn yarns (FDY), that can be tailor-made for technical as well as apparel applications.

Technical data

| DP5-S POY draw winding machine | |

|---|---|

| Type of winding | DIGICONE or precision |

| Mechanical speed | up to 1 500 m/min |

| Drive | individually driven and controlled |

| Yarn laying | fastflex electronic yarn laying system |

| Tubes/Package shape | cylindrical tubes, freely programmable |

| Traverse length | 100 – 270 mm electronically adjustable |

| Yarns | POY, FDY/FOY |

| Count range/draw force DP5-SF | PBS, PBT and PP up to 1 000 dtex PA up to 330 dtex |

| Count range/draw force DP5-SC | PES, PBT and PP up to 2 000 dtex PA up to 700 dtex |

| Number of spindles min./max. | 5/40 (single sided) |

| Supply package diameter | up to 400 mm (on stationary creel) |

Downloads

DP5-S draw heat setting winder

The energy efficient DP5-S draw heat setting machine is designed for technical and twisted filament threads such as sewing threads. The process is used to modify the textile properties of the thread such as elongation, shrinkage and tenacity as well as reduce the wavyness of the thread after dying, thereby improving the running performance of the sewing thread and the seam appearance.

Technical data

| DP5-S draw heat setting winder | |

|---|---|

| Type of winding | DIGICONE or precision |

| Mechanical speed | up to 1 500 m/min |

| Drive | individually driven and controlled |

| Thread laying | fastflex electronic thread laying system |

| Tubes/Package shape | cylindrical tubes, freely programmable |

| Traverse length | 100 – 270 mm electronically adjustable |

| Yarns | filament sewing thread, twisted technical yarn |

| Count range/draw force DP5-SF | PES and PA yarn path 11: 50 to 1 000 dtex, up to 25 N draw force yarn path 12: 50 to 2 500 dtex, up to 25 N draw force |

| Count range/draw force DP5-SC | PES and PA yarn path 12: 50 to 4 000 dtex, up to 60 N draw force |

| Number of spindles min./max. | 5/40 (single sided) |

| Supply package diameter | up to 220 mm |

Downloads

Downloads

SSM Product Range – Brochure

Contact

SSM always wants to answer queries quickly and competently.