-

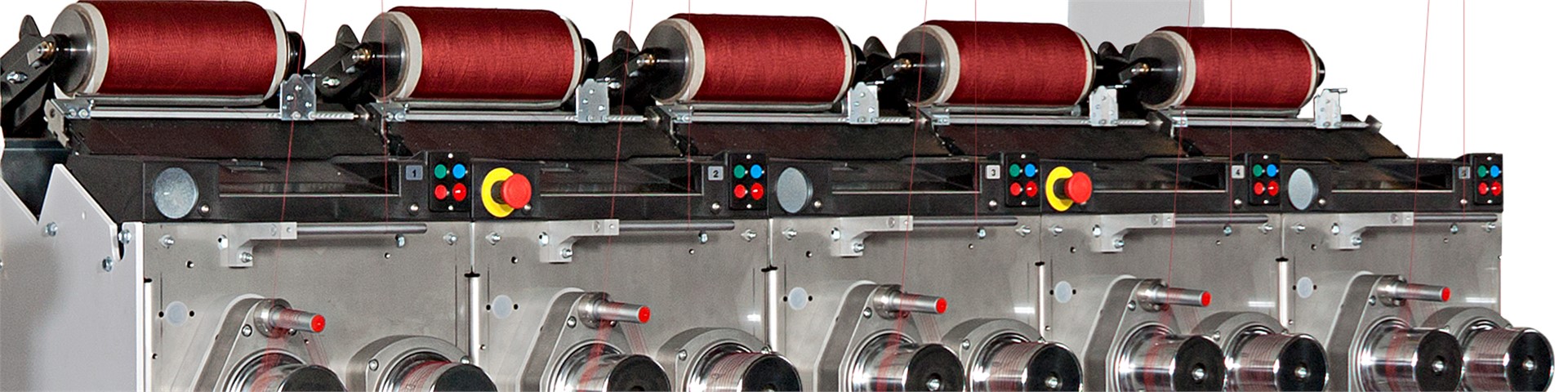

DP5-S POY 数码精密卷绕 POY 牵伸机

-

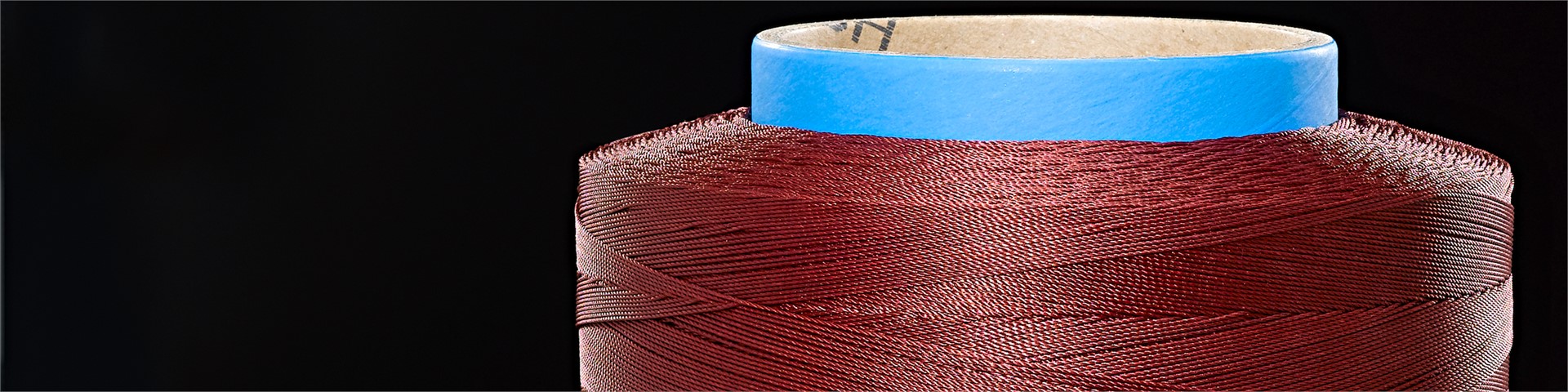

筒管

或纱管,是最灵活而广泛的卷装形状的基础(如:平行管 - 无收边 / 双锥度 - 两端收边 / 单端收边 / 瓶形),这取决于卷绕装置(卷绕形式)

-

POY预取向丝

亦称部分取向丝POY,这是化纤的主要形式。涤纶POY是涤纶切片纺丝而成的第一形态,主要用于变形。

-

FDY / FOY全牵伸丝

从合成纤维纺丝、牵伸而成。纤维被完全牵伸。FDY可直接用于纺织品加工。

-

PET / PES聚酯

由热塑性聚合物制成的合成纤维。该聚合物在其主分子链上含有酯类官能团。通常指一种叫聚对苯二甲酸乙二醇酯(PET)或聚琥珀酸酯(PES)的聚合物,熔点从103 - 106°C。

-

PP丙纶(PP)

丙纶是一种热塑性聚合物,具有广泛应用,包括包装材料和标签材料,纺织材料(如绳,保暖内衣和地毯),文具,塑料部件,各种可回用容器,实验室设备,扩音器,汽车零部件,合成纸币。其为单体丙烯加聚制成的聚合物,坚实且通常耐很多溶剂,耐酸碱。

-

PA锦纶

亦称尼龙。PA是化学纤维,从合成聚合物制成。锦纶非常耐撕裂,有弹性,可拉伸,少量吸湿。此外,其极为抗皱,也快干。

DP5-S DIGICONER fastflex™ 是专门设计用于牵伸各种 POY (包括涤纶, 锦纶和丙纶) 的牵伸卷绕机。该机具有突出的灵活性和优异的节能效果, 可成本高效地生产高质量的全牵伸丝 (FDY), 它既可以生产定制的工业丝, 也可以生产服饰用纱。

show more textshow less text

show more factsshow less factsTechnical data DP5-S (SC/SF)

Type of winding

DIGICONE® or precision

Mechanical speed

up to 1500 m/min (process speed depending on process parameters)

Package shape

freely programmable on cylindrical tube

Traverse length

100…270 mm electronically adjustable

Take-up package diameter

up to 300 mm

Package weight

up to 8 kg

Supply packages (on stationary creel)

– 1 end with reserve, package diameter up to 400 mm, tube length up to 320 mm

– up to 2 ends with reserve, package diameter up to 400 mm, tube length up to 320 mmYarns

POY, FDY/FOY

DP5-SF count range

PES, PBT and PP up to 1000 dtex, PA up to 330 dtex

(coarser counts possible depending on feed material and process parameters)

DP5-SC count range

PES, PBT and PP up to 2000 dtex, PA up to 700 dtex

(coarser counts possible depending on feed material and process parameters)Layout / N° of spindles min./max.

single sided / min. 5 / max. 40

Gauge

440 mm

Feeders / Positions

individually driven and controlled / independently driven and controlled

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral power line, ground

Installed power DP5-SF

yarn path type 1: 2.92 kW per position

yarn path type 2: 3.15 kW per position

yarn path type 3: 3.95 kW per position

yarn path type 4: 4.18 kW per position

small devices: 2.0 kW per machine

Installed power DP5-SC

yarn path type 1: 3.34 kW per position

yarn path type 2: 3.57 kW per position

yarn path type 3: 4.37 kW per position

yarn path type 4: 4.60 kW per position

small devices: 2.0 kW per machineInstalled power for options

fume exhaust system 2200 W per machine, oiling device 15 W per position

Power consumption (expected average)

20...50 % of installed power (depending on process parameters)

Recommendation for compressed air / process air requirement

compressor with a capacitiy of up to 20 m3 per position and hour with air dryer, oil filter and air tank (~ 3 m3), process air requirement min. 6 bar

Compressed air for machine operation

machine operation 6 bar, doffing 6–9 bar

Process air consumption

depending on type of jet, according to specification of jet manufacturer

Downloads

-

SSM_DP5-S_POY_1-4_cn_2020.pdf

-

筒管

-

DP5-S 数码精密卷绕牵伸热定型机

-

筒管

或纱管,是最灵活而广泛的卷装形状的基础(如:平行管 - 无收边 / 双锥度 - 两端收边 / 单端收边 / 瓶形),这取决于卷绕装置(卷绕形式)

-

FilamentYarn长丝

由一根或多根长纤维组成的合成纱线,整根丝连续。一根长丝的纱线称做单丝,多根长丝的纱线称做复丝

-

PET / PES聚酯

由热塑性聚合物制成的合成纤维。该聚合物在其主分子链上含有酯类官能团。通常指一种叫聚对苯二甲酸乙二醇酯(PET)或聚琥珀酸酯(PES)的聚合物,熔点从103 - 106°C。

-

PA锦纶

亦称尼龙。PA是化学纤维,从合成聚合物制成。锦纶非常耐撕裂,有弹性,可拉伸,少量吸湿。此外,其极为抗皱,也快干。

-

POY预取向丝

亦称部分取向丝POY,这是化纤的主要形式。涤纶POY是涤纶切片纺丝而成的第一形态,主要用于变形。

-

PP丙纶(PP)

丙纶是一种热塑性聚合物,具有广泛应用,包括包装材料和标签材料,纺织材料(如绳,保暖内衣和地毯),文具,塑料部件,各种可回用容器,实验室设备,扩音器,汽车零部件,合成纸币。其为单体丙烯加聚制成的聚合物,坚实且通常耐很多溶剂,耐酸碱。

-

PBT聚对苯二甲酸丁二醇酯

PBT与其它热塑性聚酯相似。与PET相比,PBT强度和刚性略低,但更具抗冲击性。其纤维具自然伸展,可用于混织成运动服(最常见的是泳衣)。

-

ST缝纫线

缝纫线经特殊制作以在缝纫机上快速通过。它是一种纤维状物质的细线,由二股或更多股长丝捻在一起。纱线必须在不断头或不变形的条件下形成有效的针脚。

-

TY工业用丝

该纱线用于工业纺织产品,用于非美学目的,功能(刚性,强度,尺寸稳定性,设计灵活性和经济可行性)是其主要标准。

高效节能的 DP5-S DIGICONE® fastflex™牵伸热定型机是设计用于工业丝和加捻后的长丝例如缝纫线等的牵伸热定型。该工艺可以改善纱线的如下技术特性 :

show more textshow less text

show more factsshow less factsTechnical data DP5-S (SC/SF)

Types of winding

DIGICONE® or precision

Mechanical speed

up to 1500 m/min (process speed depending on process parameters)

Package shape

freely programmable on cylindrical tube

Traverse length

100…270 mm electronically adjustable

Take-up package diameter

up to 300 mm

Package weight

up to 8 kg

Yarns

filament sewing thread, twisted technical yarn

DP5-SF count range

PES and PA

yarn path 11: 50 to 1000 dtex

yarn path 12: 50 to 2500 dtex

(coarser counts possible depending on feed material and process parameters; upon trials)DP5-SC count range

PES and PA

yarn path 12: 50 to 4000 dtex

(coarser counts possible depending on feed material and process parameters; upon trials)Layout / N° of spindles min./max.

single sided / min. 5 / max. 40

Gauge

440 mm

Feeders / Positions

individually driven and controlled / independently driven and controlled

Electrical power (basic power supply)

400 V, 50 cycles, 3 phases, loadable neutral power line, ground

Installed power DP5-SF

yarn path 11: 2.24 kW per position

yarn path 12: 3.57 kW per positionInstalled power DP5-SC

yarn path 12: 3.50 kW per position

Installed power for Options

fume exhaust system: 2200 W per machine

lubetex™ applicator: 40 W per position

lubetex™ feeding tank: 100 W per tank

oiling device: 15 W per position

Power consumption (expected average)

20...50 % of installed power (depending on process parameters)

Compressed air for machine operation

machine operation 6 bar

Downloads

-

SSM_DP5-S_11-12_cn_2020.pdf

-

筒管

SSM - Leading Swiss technology for yarn processing and winding

SSM - Leading Swiss technology for yarn processing and winding