-

Events

-

- / Frankfurt, Germany

-

Techtextil 2024

SSM at Techtextil 2024 / Hall 12, Booth C20show more show lessSSM announce their participation to the forthcoming Techtextil in Frankfurt, Germany, from 23 - 26 April 2024.

Techtextil is Europe’s leading fair for technical textiles and nonwoven products. The show is covering twelve application areas, which comprehensively span the full range of modern textile technologies. SSM presents their winding solutions for technical yarns; with the SSM DURO-TW precision winder for all technical yarns up to 50’000 dtex , SSM offers a new level of flexibility and winding quality in one machine; thereby ensuring the fulfilment of all customer requirements. For the assembly process the SSM DURO-TD allows the plying of multiple ends/yarns. Optional intermingling guarantees loop-free twists as well as optimal unwinding during twisting. The ability to run closed precision winding enables higher package densities, thereby increasing the knot-free length.With an excellent reputation for high quality textile machines and maintaining a worldwide service network, SSM is providing the maximum return on customer’s investments.

SSM will participate in the exhibition on the booth: Hall 12, Booth C20We look forward to meet you in Frankfurt.

SSM Schärer Schweiter Mettler AG

SSM announce their participation to the forthcoming Techtextil in Frankfurt, Germany, from 23 - 26 April 2024.

Techtextil is Europe’s leading fair for technical textiles and nonwoven products. The show is covering twelve application areas, which comprehensively span the full range of modern textile technologies. SSM presents their winding solutions for technical yarns; with the SSM DURO-TW precision winder for all technical yarns up to 50’000 dtex , SSM offers a new level of flexibility and winding quality in one machine; thereby ensuring the fulfilment of all customer requirements. For the assembly process the SSM DURO-TD allows the plying of multiple ends/yarns. Optional intermingling guarantees loop-free twists as well as optimal unwinding during twisting. The ability to run closed precision winding enables higher package densities, thereby increasing the knot-free length.With an excellent reputation for high quality textile machines and maintaining a worldwide service network, SSM is providing the maximum return on customer’s investments.

SSM will participate in the exhibition on the booth: Hall 12, Booth C20We look forward to meet you in Frankfurt.

SSM Schärer Schweiter Mettler AG

-

- / Lahore, Pakistan

-

IGATEX 2024

SSM at IGATEX 2024 / Hall No. 3 / Booth C-01show more show lessThe International Garment, Textile Machine and Accessories Exhibition will take place from 1 to 4 May 2024 at the Lahore Expo Centre, Pakistan.

IGATEX, the international show case of textile technology, is the one of the largest exhibition of its kind in the region. Pakistan has become a focal point for investors and has in recent years, gained recognition as an important market among other textile manufacturing countries of the region. Considered as one of the top 10 textile exporting countries of the world, Pakistan is the 4th largest producer of cotton yarn and cloth, and the 3rd largest player in Asia with a spinning capacity of 5% of total world production.

SSM will participate in the exhibition of IGATEX 2024 on the booth of our agent MAKVIZ: Hall No. 3, Booth C-01

We look forward to meet you in Lahore.

SSM Schärer Schweiter Mettler AG

The International Garment, Textile Machine and Accessories Exhibition will take place from 1 to 4 May 2024 at the Lahore Expo Centre, Pakistan.

IGATEX, the international show case of textile technology, is the one of the largest exhibition of its kind in the region. Pakistan has become a focal point for investors and has in recent years, gained recognition as an important market among other textile manufacturing countries of the region. Considered as one of the top 10 textile exporting countries of the world, Pakistan is the 4th largest producer of cotton yarn and cloth, and the 3rd largest player in Asia with a spinning capacity of 5% of total world production.

SSM will participate in the exhibition of IGATEX 2024 on the booth of our agent MAKVIZ: Hall No. 3, Booth C-01

We look forward to meet you in Lahore.

SSM Schärer Schweiter Mettler AG

-

- / Istanbul, Türkiye

-

ITM Istanbul 2024

SSM at ITM Istanbul 2024 / Hall 7, booth 702show more show lessITM Istanbul will take place from 4 to 8 June 2024 at the TÜYAP Fair Convention and Congress Center, Istanbul, Türkiye.

More than 1000 textile technology producer companies are expected to present their latest models at the largest exhibition in Türkiye.

SSM will participate in the exhibition at the Rieter booth 702, hall 7.We look forward to meet you in Istanbul

SSM Schärer Schweiter Mettler AG

ITM Istanbul will take place from 4 to 8 June 2024 at the TÜYAP Fair Convention and Congress Center, Istanbul, Türkiye.

More than 1000 textile technology producer companies are expected to present their latest models at the largest exhibition in Türkiye.

SSM will participate in the exhibition at the Rieter booth 702, hall 7.We look forward to meet you in Istanbul

SSM Schärer Schweiter Mettler AG

-

-

NewsService-News

-

-

通过数字化释放性能与增长潜力

show more show less为了在数字化之旅中为客户提供支持,最大限度地提高其数字化转型的价值,丝丝姆推出了Nema数字套件,以便随时随地对连接的机器进行近乎实时的监控。通过提供关键性能指标的清晰概览,Nema支持客户即时采取以数据驱动的行动,从而有助于最大限度地减少停机时间和浪费。纺织制造业正变得愈加以数据为驱动。该行业的主要参与者正在实施数字化转型,以实现更高的利润和更加可持续的增长。丝丝姆数字套件Nema用于收集信息,以便做出基于数据的决策,帮助缩短停机时间,提高产能和改善质量。它还有助于客户随时随地快速轻松地将成功复制到任何连接的机器上。

及早发现、快速行动、缩短停机时间

在生产过程中很难及时检测到任何故障,等到发现时往往为时已晚。Nema几乎实时监测与机器正常运行相关的数据,如机器和锭位故障、警告等,并将这些数据传输到仪表板,以提供全局概览。系统会对任何偏差发出警报,以便及早检测到异常。可及时做出基于数据的决策,从而限制代价高昂的停机、成本和收入损失。快速将成功复制到其他设备

通过跟踪关键性能指标,Nema使客户能够识别机器运行性能最佳的条件。然后,可以轻松复制这些条件,以确保整个机组都能高效生产。AMANN将效率提高5%

AMANN是国际领先的生产商之一,致力于为工业纺织品提供优质的缝纫线、刺绣线和高档纱线。作为其领域的创新者,该公司率先使用Nema来监管其八个生产基地的机器性能。仅在三个月后,AMANN就优化了其制造工作流程,将效率平均提高了5%以上。实时数据正成为纺织行业的标准。通过几乎实时的监控和对生产数据的智能利用,Nema在正确的时间提供正确的见解,以释放整个绕线机机组的所有潜力。

更多信息请联系

SSM Schärer Schweiter Mettler AG

-

-

Towards a Powerful Market Entry into the Sewing Thread Business with SSM

show more show lessSagar Metallics, India’s largest producer of metallic yarns, has decided to enter the production and selling of sewing thread. The company is counting on SSM to accompany them on this exciting journey and is acquring several hundred positions of the sewing thread finish winder Thread King III and the precision package winder NEO-BW, all connected to Nema, SSM digital suite.-

Sagar Metallics and SSM signed a contract at ITMA Milan 2023. From left to right: Dr. A. T. Narayanan, General Manager, SSM India; Carlo Naegeli, SSM India; Madan Wajpe, M.D. SHIVAM Group; Suresh Patel, M.D. Sagar Metallics, Per Olofsson, M.D. SSM; Mayank Patel, E.D. Sagar Metallics; Abhijeet Erande, AGM SHIVAM Group; Roman Haefeli, Head Sales & Marketing SSM -

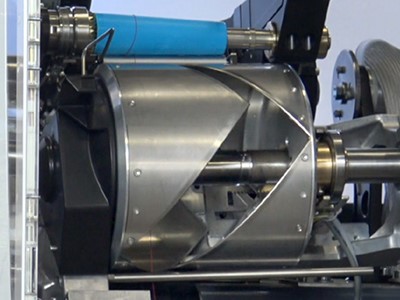

The automatic slit-drum opener, a unique feature of the Thread King III -

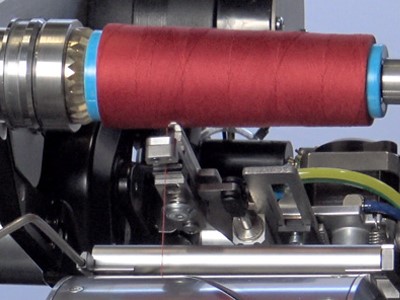

The NEO-BW ensures highest production speeds at lowest possible operation costs

Turning strategy into action

To turn their new strategy into success, Sagar opted for the most performing solutions available on the market. With the Thread King III, Sagar is sure to have the most efficient winder with a shorter production cycle, easier thread-up of the yarn, reduced machine footprint and lower power consumption. The company also purchased the precision package winder NEO-BW for its outstanding productivity performance and will connect all machinery to Nema, ensuring key performance indicators in near real-time.

Building long-term success together

As the world’s leading supplier of sewing thread finish winders, SSM always brings innovative solutions to ensure its customers’ competitiveness. The Thread King III sewing thread finish winder has the shortest doffing cycle on the market, up to 40% shorter than its previous version. The new winder benefits from improved length measuring accuracy resulting in 50% reduction of the safety margin on wound packages, thereby saving 1% raw material.

The NEO-BW achieves high productivity and reproducibility for a minimum off-shade dyeing. It features a unique thread laying system allowing highest production speeds at lowest operation costs.

Nema provides near real-time monitoring and gives a global vision which allows customers to compare key performance indicators. Best practices can easily be identified and duplicated to boost the entire production.

SSM is proud to be a partner of choice for Sagar and to contribute to expanding the success of the company in sewing thread with innovative and ultra-efficient machinery and digital solutions.

For more information about SSM solutions please contact:

SSM Schärer Schweiter Mettler AG

Rütihof 8, CH-8820 Wädenswil / Switzerland

L_hc__mss--ofni, www.ssm.ch -

-

-

Thread King III绕线王3 – 重温经典

show more show less新一代Thread King绕线机不负众望。它实现了效率与可持续性的完美组合,缩短了生产周期、简化了生头、减少了机器碳足迹并降低了能耗。-

图1:Thread King III是市场上最高效的绕线机之一,具有无可比拟的价值。 -

图2:与TK2相比,专利保护的自动塞纱尾系统可将落纱周期缩短40%。 -

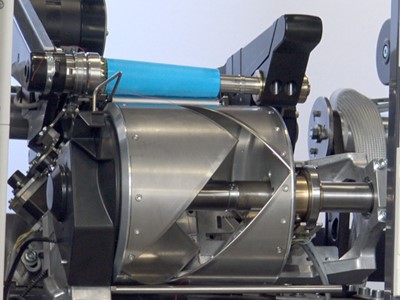

图3:TK3的特色功能,裂缝式转鼓自动打开。

Thread King绕线机的名声首屈一指。多年来,先进技术的不断注入,让它在竞争中始终保持领先地位。新一代Thread King III (TK3)绕线机增加了纱管供应容量,将落纱周期缩短达40%并节约了大约1%的原料,从而变得前所未有地高效。该机器还具备物联网功能,并可以选配丝丝姆数字套件Nema。

推动缝纫线生产超越极限

Thread King III绕线机(图1)以效率为本。得益于专利保护的自动塞纱尾系统(图2),TK3具有市场上最短的落纱周期,比前代产品缩短达40%。它是同类产品中首款采用裂缝式转鼓自动打开的设备(图3)。这便于快速单手生头、轻松维护和清洁,从而节省大量时间。锁在封闭护罩中的卷绕头充分保障了操作人员的安全。在可持续发展方面,TK3实至名归。TK3的设计经过优化,以减少机器的碳足迹。Thread King III绕线机的速度高达15000转/分,生产周期短:同样的产能,所需的机器更少,并降低了能耗,减少了浪费,从而更具可持续性。

以节省成本为驱动

新型绕线机可从更高的长度测量精度中受益。这一超精准的测量功能允许将卷装的安全裕度降低50%,从而节省了1%的原料。此外,Thread King III绕线机还配备了创新的丝丝姆preciforce系统,这是首套允许在线调节背压力的系统,从而能够实现精确的卷装成形,而不会出现密度或直径偏差。这款第三代Thread King绕线机还配备了新型lubetex高精度润滑系统。lubetex系统可实现超高精度上油,这对环境和成本具有积极的影响。

从喇叭筒子到宝塔筒子

同其前代产品一样,TK3具有两个版本:用于加工宝塔筒子的TK3-CT和用于加工喇叭筒子的TK3-KT。与前代机型相比,TK3对喇叭筒子的纱管供应容量翻了一番,对于宝塔筒子,甚至翻了两番,具体取决于纱管大小。两款机器均能实现尽可能高的卷装和纱线质量。具有不同执行方式的另外两个版本正在规划中。凭借Thread King III,丝丝姆巩固了其在绕线机市场领域的领导地位。这款先进的机器可提高客户的盈利能力,同时实现卓越的质量,并有助于显著节省成本。

更多信息请联系

SSM Schärer Schweiter Mettler AG

-

-

-

凭借XENO-AC实现无可挑剔的品质

show more show lessBishnu Texport Pvt. Ltd.是氨纶纱的先驱之一,生产超细旦空气包覆纱。自2003年创立以来,该公司迅速发展壮大并扩大了其产品组合,包括传统的单包覆纱和双包覆纱。Bishnu以其卓越的品质而著称,致力于帮助客户取得成功,并不断扩大其产品组合以满足客户需求。面临的挑战

为更好地及时响应客户的需求,Bishnu Texport Pvt. Ltd.决定自行生产空气包覆纱。从贸易公司向制造公司的转型并非一帆风顺,其中充满了各种挑战。该公司致力于一个雄心勃勃的目标——在缩短交货时间和 降低进口成本的同时实现同等甚至更高的质量。为找到市场上最好的空气包覆纱机,Bishnu转向了丝丝姆。尽管有更便宜的替代产品,但该公司相信,对丝丝姆空气包覆纱机的原始投资将带来更高的投资回报率,而且更符合其“对质量零妥协”的理念。

解决方案

2012年,Bishnu在其位于印度北部德里附近的工厂引进了15锭丝丝姆 DP3-C空气包覆纱机。该工厂的工作 温度在3到45摄氏度之间变化,这对于生产10/10旦聚酰胺和氨纶超细纱来说是一个严峻的挑战。凭借合适的空调系统和丝丝姆专家的大力支持,Bishnu成功安装好了机器,并实现了顺利可靠的生产。在2020年,该公司引进了90锭XENO-AC空气包覆纱机,是公认的高品质空气包覆纱品牌。

客户收益

XENO-AC机器的主要优势在于成品质量。从纱线质量到机器运行性能,再到卷装外观,一切都得到了优化。10年来,Bishnu及其客户一直享有稳定的卓越品质,公司的客户群也在不断壮大。Bishnu目前正在向日本和斯里兰卡出口其空气包覆纱,并计划在日本长期开展业务。因此,公司计划 到2025年年底将其现有的丝丝姆空气包覆纱机的锭数增加至200锭。

更多信息请联系

SSM Schärer Schweiter Mettler AG

-

-

India ITME 2022: Rieter Strengthens Success of Spinning Mills

show more show less• Autoconer X6 – key machine for highest efficiency

• Compacting solutions – full flexibility adds competitive edge

• Spin it again – recycling expertise for rotor and ring yarns

• ESSENTIALorder – purchasing parts with a few clicks

• ROBOspin – the solution for personnel shortages

• SSM NEO-FD – proven technology for efficient twisting production

• Temco CoolFlow disc – innovation that delivers longer lifetimeRieter is presenting the latest innovations in its systems, components and services at the upcoming India ITME 2022 in Uttar Pradesh (India), taking place from December 8 – 13, 2022. The company’s technology portfolio is designed to help customers succeed in markets shaped by rising energy and raw material costs.

Autoconer X6 – Key Machine for Highest Efficiency

The automatic winding machine Autoconer X6 perfectly completes the Rieter ring and compact-spinning systems. The machine serves as the final quality assurance in the ring and compact-spinning process and is key to the performance of the subsequent process stages. The Multilink system with Multilot offers maximum flexibility to handle a different type of yarn.

The latest splicer generation OZ1 and OZ2 provides an optimum splice quality based on an open prism. With only two prisms spinning mills can splice the entire spectrum of cotton yarns as well as blends. They are also used for the splicing of cotton-based elastic core yarns in combination with the Elastosplicer. The splice zone exhibits an impressive elasticity in the fabric.

Full Flexibility with Compacting Solutions

The Rieter compacting devices – COMPACTapron, COMPACTeasy and COMPACTdrum – are the right solution for every application. Spinning mills can change quickly between ring and compact yarn and offer customers a broader product range. This gives them an edge in the market.

Spin it Again: Recycling Expertise from Rotor to Ring

Rieter offers solutions for the integration of recycled raw material into yarn production to help close the textile loop and make fashion more circular. Both rotor and ring yarns can be produced with a considerable amount of mechanically recycled fibers. The result is promising: Garments made of challenging post-consumer material can be attractive for both consumers and the environment.

ESSENTIALorder – Purchasing Parts with a few Clicks

Based on existing customer information, the webshop ESSENTIALorder visualizes which Rieter machines and systems are available inside each spinning mill. It therefore offers a personalized shopping experience and facilitates order management, enabling spinning mills to optimize their internal stock levels. ESSENTIALorder is available 24 hours a day, seven days a week.

ROBOspin – the Solution for Personnel Shortages

The piecing robot ROBOspin reduces personnel requirements in the ring spinning section by 50%. The robot also attains productivity increases thanks to higher spindle speeds at equal or higher efficiency.

SSM NEO-FD for Efficient Twisting Production

SSM is presenting NEO-FD, the assembly-winding machine for precision wound packages for twisting. It meets all requirements for efficient production. The machine features the auto-doffing option and the online back-pressure system for low and high package densities. With ergonomic design and proven technology, the machine cuts maintenance and service costs to a minimum.

Temco CoolFlow Disc with Longer Lifetime

Temco’s CoolFlow texturing discs offer longer lifetime thanks to a brand-new geometry and the latest polyurethane technology. The texturing discs now generate a disc surface that operates at a lower temperature, resulting in slower ageing and abrasion. Further benefits are more stable yarn quality, higher productivity, and an overall process cost reduction.

Visit Rieter at INDIA ITME 2022 at India Expo Centre & Mart, Greater Noida, Uttar Pradesh 201306, India from December 8 – 13, 2022 in hall 10 at booth H10C11.

-

-

Becoming the Amazon of Yarns

show more show lessHow TURKTEX responds in no time to customers’ demands and offers over 1 000 different yarns.-

Fig.1: With SSM DP5-T, TURKTEX provide high quality Air Textured Yarn (ATY) -

Fig.2: Mr. Ömer Efendioğlu, plant manager at TURKTEX, is very satisfied with the great support from SSM -

Fig.3: Mr. Dündar Cetin, owner of TURKTEX, appreciates working with a company who shares the same values and is dedicated to delighting its customers

In the fast-paced market of synthetic yarns, answering the ever-increasing customers’ demands in a timely manner is a crucial competitive advantage. Since 2002, the synthetic yarn manufacturer TURKTEX has excelled at finding newer, better, and faster ways to satisfy its customers’ demands, almost in no time. With SSM DP5-T, TURKTEX takes its competitiveness and mission towards customers to the next level.

The independent Turkish textile company, TURKTEX, focuses on the world of synthetic yarns, and is a brand of Turkuaz Tekstil San. ve Tic. A.Ş. group. Founded in 2002, in Bursa, Turkey’s textile hub, TURKTEX has relied on SSM texturing machines from the very beginning, enabling the company to respond to customers’ demands with innovative, fast and flexible solutions.

Due to its superior products, TURKTEX is now Turkey’s leading company in the high value-added continuous filament sector, especially for polyester (PES) and polypropylene (PP) yarns. Its production portfolio includes yarns for home textiles (such as curtains, upholstery, mattress ticking and carpets), fashion, automotive fabrics as well as yarns for technical applications, outdoor and military. Besides supplying the local market, the company exports its products to more than 30 countries.

The largest portfolio to meet customers’ demands at any time

TURKTEX has the ambition to become the Amazon of yarns, that is the biggest synthetic yarn retailer. With a huge portfolio including polypropylene (PP) or polyester (PES) in divergent forms (recycled, flame retardant and more), various final yarn counts up to 2 000 denier, each available in 50 different colors, the company is on track to succeed.

DP5-T: the right solution to handle large assortments

In order to provide its huge range of yarns with short lead times, TURKTEX is dependent on reliable, fast, flexible and easy-to-use machines that are also quick and simple to maintain.

SSM machines have proved to be the perfect solution. In 2020, TURKTEX acquired the last SSM texturing machine DP5-T to help the company meet the demand in Air Textured Yarn (ATY) made of PES and PP (Fig. 1). It then invested in a DP5-FT false twist-texturing machine to drive business in the Drawn Texturized Yarn (DTY) market as well.

Today, the company stores approximately 1 000 different recipes in its SSM DP5-T machines and changes around every other second day the settings of the spindles. Any recipe can be removed and put back into production without any quality or repeatability issues. With its individual drive concept, the DP5-T makes it easy to switch between recipes, an indispensable feature for TURKTEX as it responds to the ever-changing needs of its markets.

TURKTEX is very satisfied with SSM’s support, service and technicians. Plant Manager, Mr. Ömer Efendioğlu (Fig 2.), highlights: "SSM cares about our needs and supports us from the first negotiation to the commissioning of the machine and beyond."

Flexibility, fast response and excellent quality

TURKTEX has a strong internal textile research and development department which ensures innovative products. To make these products a reality in the desired quality, the company can count on SSM. Mr. Dündar Cetin (Fig. 3), owner and technical director of TURKTEX, is convinced that it is crucial to satisfy customers' requirements immediately and without delay. He states: "Always keeping promises and ensuring excellent quality is possible for us, thanks to SSM DP5-T."

Flexibility is another critical factor. While standard batches in the industry are usually over 2 tons, TURKTEX handles many small orders, as low as 50 kg. Changing raw material and parameters can be laborious, but with the DP5-T, it is easy for operators to switch between orders.

In summary, Mr. Cetin says: "I am really very happy about the cooperation with SSM because we follow the same values with our identical slogan: Flexible, Fast, Safe."

For further information please contact:

SSM Schärer Schweiter Mettler AG

L_hc__mss--ofni . www.ssm.ch -

-

-

ITM 2022: Rieter Further Improves Attractiveness of Ring and Compact-Spinning System

show more show less• European roll out of precision winder NEO-YW to launch in Turkey

• Roving frame F 40 sets industry standard at 90 seconds only for doffing

• New top and bottom aprons NO-79201 offer greater durability

• i-Bearing enables 24/7 visibility for fast and smart decisions

• Berkolizer pro introduces easily adjustable UV treatment as industry-first

• Autoconer X6 is the key machine for highest efficiencyRieter is presenting the Autoconer X6 at the upcoming ITM 2022 in Istanbul (Turkey), taking place from June 14 to June 18, 2022, which further improves the attractiveness of the company’s ring and compact-spinning offering by completing the system. In addition, Rieter is showing the roving frame F 40 which doffs at 90 seconds only. SSM’s NEO-YW precision winder is launching into the European market while three key innovations in components are being introduced.

The Autoconer X6 is a globally recognized winding machine at the highest performance level, putting it on a par with all other Rieter machines. The winding machine serves as the final quality assurance in the ring and compact-spinning process and is key to the performance of the subsequent process stages.

The latest splicer generation OZ1 (Ne 20 to Ne 120 and finer) and OZ2 (Ne 3 to Ne 40) provides an optimum splice quality based on an open prism. When splicing cotton-based elastic core yarns, duo-core yarns and multi-core yarns, the open prisms are used in combination with the Elastosplicer. This has already been successfully introduced in vertically integrated mills.

The new Multilink system with Multilot offers maximum flexibility: Up to four ring spinning machines are linked to one Autoconer, with each ring spinning machine able to supply a different type of yarn.

With the integration of the Autoconer X6 into the Rieter system, the mill management system ESSENTIAL will open up over the coming years the potential for end-to-end transparency and optimization throughout all process steps.

The roving frame F 40 was already introduced to the market at ITMA 2019. A precise bobbin build-up in combination with a doffing time of 90 seconds only and the option of setting the drafting system electronically are convincing customers to invest in this machine in combination with Rieter systems.

SSM is presenting the NEO-YW precision winder which brings to bear SSM’s unmatched winding expertise into one easy-to-use and high-performing machine. NEO-YW will kick off its launch into the European market at ITM 2022.

Components for Higher Performance and Durability

The newly acquired Accotex and Temco brands are adding strength to the components family, which now includes Accotex, Bräcker, Graf, Novibra, SSM, Suessen and Temco. Rieter is presenting three key innovations at ITM.

Accotex’s new top and bottom aprons NO-79201 offer outstanding tear and abrasion resistance and superior friction properties. They can be applied universally, making service and stocking more efficient.

Temco’s intelligent bearing solution i-Bearing for filament machines allows condition monitoring online. By identifying critical conditions, bearings can be replaced before they fail which helps to minimize machine downtimes.

Today, Bräcker’s berkolizing technology of treating rubber cots with UV light to improve the surface has become an industry standard. At ITM, Bräcker is introducing the berkolizer pro which stands for consistent, energy-efficient, and adjustable UV treatment.

Opportunities and Challenges to the Spinning Industry

2021 was an unprecedented year for the global spinning industry. Driven by the market recovery after the pandemic and the regional shift of the industry, customers invested in new spinning systems at levels never experienced before. And despite the current uncertainties, customers continue to invest.

As market and technology leader, Rieter succeeded in this environment in posting a record order intake for 2021. This is clear evidence of the high level of trust customers have in Rieter. Dr. Norbert Klapper, CEO of Rieter, says: “Systems, machines, components, parts and services from Rieter have ensured competitiveness and success for customers over many years in the past and will continue to do so in the future.”

Dr. Klapper also comments on the challenges that lie ahead for the industry as it takes advantage of market opportunities: “The pandemic is not over yet, and business is exposed to dramatic cost increases as well as shortages in material supplies and logistics. In difficult times, it is important to work together even more closely than under normal circumstances. It’s all about true partnership and trust – the basis of Rieter’s business for 226 years.”

Visit Rieter at ITM 2022 at TÜYAP Fair Convention and Congress Center, Istanbul, Turkey, from June 14 to 18, 2022 in hall 3-314 at booth C07. Register to experience our virtual booth from anywhere, anytime via [www.rieter.com/company/virtualworld] with the ITM 2022 edition going live June 10, 2022.

-

-

Digital potentiometer

show more show lessSSM has launched the digital potentiometer for most of its existing machines to create a strong foundation for a consistent bobbin quality and reduce maintenance work. The retrofit on the machine can easily be done on single spindles. A section can therefore contain different potentiometers from different generations. Some older machines will require a software update.Customer benefit

Seize the opportunity to exchange your analogue potentiometer with a digital one and profit from various advantages. The new potentiometer enables 400 times more measuring cycles than the analogue potentiometer. Additonally, an important improvement is a more accurate and stable signal with an exact resolution and no drift. Further, there is also no wear and tear side effect for this spare part.

All customers with machines as mentioned on the flyer, no matter which PCB, can profit from this new retrofit kit.

Download the "Retrofit Digital Potentiometer" flyer HERE and ask our service support for an offer.

Please do not hesitate to contact us for further information about SSM service solutions at L_hc__mss--troppus

SSM Schärer Schweiter Mettler AG

-

-

SSM:络筒背后的科学奥秘

show more show less每一家纺纱厂都渴望能够加工出完美的卷装,以方便染色或织造等后道工序处理纱线。阅读本文,了解如何实现完美的卷装,以及为何这是一项有助于节约能源和资源的卓越工程成就。卷绕是纺织价值链中一个小而关键的工序。在这一工序中,纱线被紧密地卷绕在筒管上,为下一道生产工序做好准备。每一家纺纱厂都渴望能够加工出完美的卷装,以方便染色或织造等后道工序处理纱线。

preciforce树立全新标杆

实现完美卷装的秘诀是要确保整个卷装达到一致的密度,这对于染色工序尤其重要。然而,这是一项表面看似简单,实则需在数十年专业知识的基础之上精心设计才能得以实现的工程成果。就在不久之前,卷绕系统还只能监测密度,而不能调节压力水平。SSM的preciforce改变了这一切,它能够调节背压力,使每一个卷装都能达到相同的密度。密度均匀的卷装可简化染色工序,进而实现更佳的染色效果。更为重要的是,染厂可节约能源和水资源,因为再也没有必要进行复染。而复染恰是不均匀卷装染色所无法避免的。

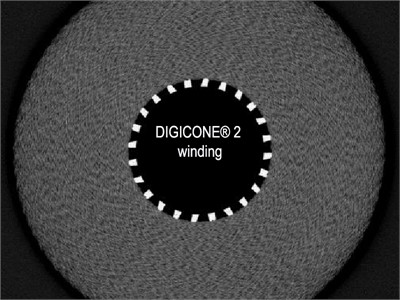

致胜组合:preciforce与DIGICONE 2

出色的密度均匀性确实重要,但控制成本同样意义重大。SSM公司的使命是帮助客户以尽可能低的成本和最少的浪费进行生产。卷绕是一套重复性操作,SSM工程师发现,对谷歌搜索和算法交易有用的办法对卷绕也一样行之有效,因为这些都是基于重复的连续性操作。他们开发了一种算法,以确保络筒机按照分步式程序,以最经济的方式实现紧密卷装。DIGICONE 2采用这种先进的卷绕算法开发,以确保实现最佳的卷绕精度。preciforce与DIGICONE 2构成了一个无懈可击的组合,能够以最经济的方式生产出卓越的卷装。此外,与普通的自动背压力系统相比,preciforce可节省约20%的能源。

SSM机器的卓越可靠性则进一步完善了这个组合,保证了机器以及备件都具有最长的使用寿命。SSM还提供世界一流的服务网络,在全球拥有10多个当地服务中心和80余家代理机构。这意味着离客户近和快速客户响应。

-

-

Conversion traverse unit TW1/2

show more show lessAll customers with TW1/TW2 machines get the chance to upgrade their TW1/2 machines with a new traverse unit kit. The conversion requires the customer to replace the existing traverse units with TW2plus. This upgrade enables the customers to maintain the performance of their TW1 and TW2 machines at a high level over the whole lifetime.The main advantage of this retrofit for the customer lies with faster and more powerful motors. Due to stronger motors the speed can be increased, default rate can be decreased and lifetime of motors is longer. All factors have a very positive impact on productivity, which is a key criteria for production.

Download the "Conversion Traverse Unit TW1/2" flyer HERE and ask our service support for an offer.

Please do not hesitate to contact us for further information about SSM service solutions at L_hc__mss--troppus

SSM Schärer Schweiter Mettler AG

-

-

More accurate length measuring on PW machines

show more show lessSSM has launched a new support-roller sensor for cylindrical tubes to significantly reduce the variation in length measuring. Accuracy of up to +/- 0.3% can be achieved with the new kit consisting of software and mechanical parts. The retrofit on the machine can easily be done on single spindles.Customer benefit

Customers with PW1/2/3/8/X machines and cylindrical tubes profit from clear advantages in length measuring. Already when re-/winding 5000m of yarn the improved accuracy on length can be felt.

Further, there is less waste in the downstream process which results in a higher profitability for the customer. SSM already offers this option for other machines with great success and is pleased to make one of the latest length measuring technologies available to its customers.Once customers decide to upgrade their machines, they will benefit from improved accuracy and save money due to less waste.

Additional spare parts

All customers with PW machines, which are equipped with a Multiflex, Smartflex or a Precicontrol PCB can profit from this new kit. The following spare parts are required to improve the length measuring substantially: magnetic sensor, aluminium support, support roller with magnet ring, rubber-seal, software.

Download the "Support Roller Sensor PW" flyer HERE and ask our service support for an offer.

Please do not hesitate to contact us for further information about SSM service solutions at L_hc__mss--troppus

SSM Schärer Schweiter Mettler AG

-

-

Extend machine lifetime for 10 years

show more show lessRetrofits are often very popular and worthwhile, if they enhance the lifetime of a machine. All customers who have a PW1, PS6 or PS6plus and decide to change their spindle control unit can upgrade from Precicontrol or preciflex™ to Smartflex.A big advantage of Smartflex is that the control unit does not require any backup batteries and is therefore more stable than Precicontrol or preciflex™. Upgrading electronics of the machine can prolong its usability for additional 10 years.

With a Smartflex upgrade, SSM customers have clear advantages. Not only can they continue to use well maintained machines for another 10 years, but they also save money and add their share to a sustainable environment for consumers. Additionally, the new system is more stable which facilitates handling and maintenance. Latest version of machine terminal with coloured display and state-of-the-art electronical control board results in a significant improvement of the system communication, less break downs and higher machine efficiency.

Download the "Retrofit to Smartflex" flyer HERE and ask our service support for an offer.

Please do not hesitate to contact us for further information about SSM service solutions at L_hc__mss--troppus

SSM Schärer Schweiter Mettler AG

-

-

DIGICONE®2第二代数码卷绕技术 - SSM缔造完美纱线卷装

show more show lessSSM软件经理Goeksel Karaarslan熟知经过恰当卷绕的优异卷装所具备的特性:均匀的密度,没有明显的表面结构,正如专家所说的,“没有重叠”。这点非常重要,因为纱线卷装只有经过恰当卷绕,才能均匀充分地吸收染料。 Karaarslan.说“没有人想穿带色斑的衣服”另外,优异卷装更有助于下道工序的高效加工。纱线以及卷装的多样性 - 特殊挑战

问题是:络筒机通常不能够直接生产出易于染色的卷装,这是由于存在粗支纱,低支纱,粗糙纱细,光洁纱线,圆柱形卷装以及圆锥形卷装 … 其原因数不胜数。优异的络筒机会将所有的参数都考虑进去,同时,能持续稳定地生产高品质卷装。一旦纱线卷装以不理想的方式卷绕,这种状况会导致下道工序出现问题,从而使得产品处于劣势。这种劣势会消耗大量的时间与金钱,这也正是竞争激烈的纺织行业的致胜要素。因此,SSM与著名的大学合作,开发出特定的纱线排列程序,无论何种纱线,均可使络筒机能够卷绕出完美的卷装。

以图像取代实验室测试

工程师们和数学家们选择特殊的方法,他们并不是测量纱线张力,线密度,材质以及纱线直径,并将这些参数集合至复杂的公式中,而是将SSM的专业知识转化为理论,这样做能够对筒子纱的结构以及密度分布精准预测。从数论中运用这些方法,最终专业技术人员能控制络筒过程中的“混乱动态系统”。以这套算法为基础,开发出的DIGICONE®2算法能嵌入到络筒机控制系统软件中。通过络筒过程中的高速记录以及借助X线计算机层析成像技术,最终证实了SSM在这一项目上的成功(见对比图像)。结纶:相同结构的络筒机,之前并不总能卷绕出容易染色的筒子,而通过新的软件控制,则达到了这样的目的。

创新带来的竞争力优势

由于SSM与著名大学的合作,这一想法得以最佳地实施。Karaarslan说“DIGICONE®2算法使得我们能够在络筒机的市场上保持领先地位”。目前这种算法已经成功地运用在最新一代SSM机器上,顾客也已实质性地从中获益。

更多有关SSM的解决方案,请联系:

SSM Schärer Schweiter Mettler AG

Neugasse 10, CH-8810 Horgen / Switzerland

L_hc__mss--ofni, www.ssm.ch

-

-

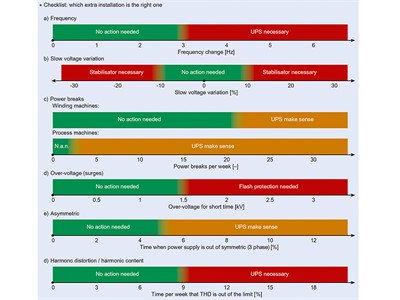

Electricity supply for SSM machines

show more show lessJust like all modern textile machines SSM machines rely on a stable electricity supply to function correctly. A stable supply also extends the lifetime of the electronic boards and makes the machine more efficiently.What’s a stable electricity supply?

An electricity supply is characterized by frequency, magnitude, waveform and symmetry of the three-phase-voltages. If the following disturbances exceed certain limits then the quality will be affected:

• main power shortages

• jitter light

• voltage variations

• frequency variations

• slow and rapid voltage changes (over-voltage, spikes)

• unbalance of three phase voltage

• harmonic distortion

An exact definition of a stable supply is given in the European Norm (ex. EN50160). SSM assures its machine function correctly if the norm is fulfilled.

How to test the electricity supply

To test if a supply is inside the norm you have to analyse your net over a long time. Variations over the seasons have to be taken into consideration (summer/winter influences etc.). Often a weekly analyse will give you sufficient information about your net. SSM can offer a short analyse of your net. Very often though consumers know their supply. Important are the amount of main power shortages and voltage variations.

How to connect the machine to the supply

A lot of errors can be avoided by connecting a machine correctly:

• Is the grounding system of the machine correct?

• Sufficient cross section of the supply pipe?

• Avoid connecting machines of different power classes to the same main distributor.

How to protect a machine

There are a number of devices that can help to protect a machine, e.g. UPS (unbreakable power interrupt), power stabiliser, flash protector, or net filter. It is important to choose the best and most economical solution. The beside checklist will help you to choose appropriate equipment.

-

-

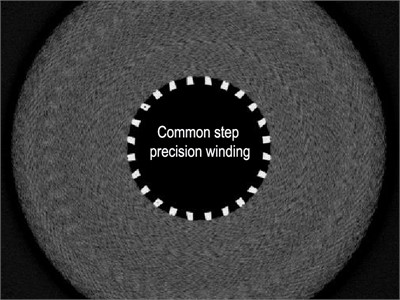

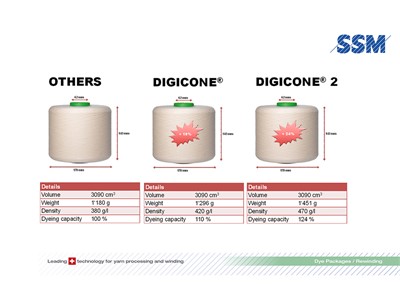

SSM DIGICONE® 2 -Advanced winding algorithm

show more show lessDIGICONE® step precision winding – developed by Schweiter in the 1970s – combines the advantages of random winding and precision winding.The ratio between double strokes and number of revolutions is kept constant for a certain diameter range. The crossing angle varies only slightly within a range of ±1°. This results in an enhanced package density that does not change with increasing package diameter. So the building of pattern zones is avoided and the package maintains a stable structure without any ribbons. Due to this stable structure, the risk of complete layers “slipping off” during the unwinding process of dyed packages, as known with random winding, is completely eliminated.

The introduction of the XENO platform opened new possibilities for optimizing the winding algorithm. Thanks to this new machine platform, SSM could release DIGICONE® 2, enabling an increase of dye package density by another 10–24% with unchanged dyeing recipes.

For more information about SSM solutions please contact:

SSM Schärer Schweiter Mettler AG

Neugasse 10, CH-8810 Horgen / Switzerland

L_hc__mss--ofni, www.ssm.ch

-

SSM - Leading Swiss technology for yarn processing and winding

SSM - Leading Swiss technology for yarn processing and winding