Service-News

-

-

NewsService-News

-

-

Digitization to Unlock Performance and Growth Potential

show more show lessTo support customers on their digital journey and maximize the value of their digital transformation, SSM presents Nema, a digital suite allowing near real-time monitoring of connected machines, anytime, anywhere. With a clear overview of key performance indicators, Nema supports customers in taking data-driven actions in a timely manner and thus helps minimize downtime and waste.Textile manufacturing is becoming more and more datadriven. Key players in the industry are embracing the digital transformation to enable a more profitable and sustainable growth. Nema, SSM digital suite, gathers information leading to data-based decisions, less downtime, higher productivity and better quality. It also helps customers to quickly and easily duplicate success to any connected machines, anywhere.

Early detection, quick action, lower downtime

Timely detection of any fault during the production process is difficult and often comes at too late a stage. Nema tracks machine health-related data such as machine and position errors, warnings, etc. in near real-time, and transmits these data to a dashboard, thus providing a global overview. The system alerts about any deviation for an early detection of abnormalities. Data-based decisions can be made in a timely matter, thus limiting expensive downtime, costs, and loss of revenue.

Quickly duplicating success to other plants

Tracking key performance indicators, Nema enables customers to identify the conditions of the best performing machines. These conditions can then easily be replicated to ensure a high production level, throughout the entire machine fleet.

5% higher efficiency at AMANN

AMANN is one of the leading international manufacturers of high-quality sewing threads, embroidery threads and smart yarns for technical textiles. Being innovators in its field, the company is one of the first to use Nema to oversee the performance of its eight production sites. After only three months, AMANN optimized its manufacturing workflows, resulting in more than 5% higher efficiency on average. Real-time data is becoming a standard in the textile industry. Through near real-time monitoring and a smart utilization of production data, Nema gives the right insights, at the right time to unlock the full potential of the entire winding machine fleet.

For more information about SSM solutions please contact:

SSM Schärer Schweiter Mettler AG

Rütihof 8, CH-8820 Wädenswil / Switzerland

L_hc__mss--ofni, www.ssm.ch

-

-

Towards a Powerful Market Entry into the Sewing Thread Business with SSM

show more show lessSagar Metallics, India’s largest producer of metallic yarns, has decided to enter the production and selling of sewing thread. The company is counting on SSM to accompany them on this exciting journey and is acquring several hundred positions of the sewing thread finish winder Thread King III and the precision package winder NEO-BW, all connected to Nema, SSM digital suite.-

Sagar Metallics and SSM signed a contract at ITMA Milan 2023. From left to right: Dr. A. T. Narayanan, General Manager, SSM India; Carlo Naegeli, SSM India; Madan Wajpe, M.D. SHIVAM Group; Suresh Patel, M.D. Sagar Metallics, Per Olofsson, M.D. SSM; Mayank Patel, E.D. Sagar Metallics; Abhijeet Erande, AGM SHIVAM Group; Roman Haefeli, Head Sales & Marketing SSM -

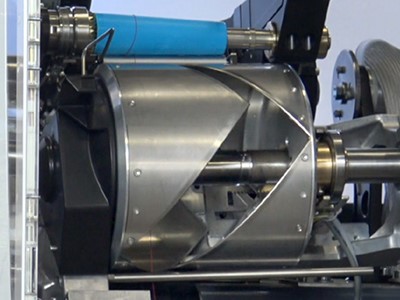

The automatic slit-drum opener, a unique feature of the Thread King III -

The NEO-BW ensures highest production speeds at lowest possible operation costs

Turning strategy into action

To turn their new strategy into success, Sagar opted for the most performing solutions available on the market. With the Thread King III, Sagar is sure to have the most efficient winder with a shorter production cycle, easier thread-up of the yarn, reduced machine footprint and lower power consumption. The company also purchased the precision package winder NEO-BW for its outstanding productivity performance and will connect all machinery to Nema, ensuring key performance indicators in near real-time.

Building long-term success together

As the world’s leading supplier of sewing thread finish winders, SSM always brings innovative solutions to ensure its customers’ competitiveness. The Thread King III sewing thread finish winder has the shortest doffing cycle on the market, up to 40% shorter than its previous version. The new winder benefits from improved length measuring accuracy resulting in 50% reduction of the safety margin on wound packages, thereby saving 1% raw material.

The NEO-BW achieves high productivity and reproducibility for a minimum off-shade dyeing. It features a unique thread laying system allowing highest production speeds at lowest operation costs.

Nema provides near real-time monitoring and gives a global vision which allows customers to compare key performance indicators. Best practices can easily be identified and duplicated to boost the entire production.

SSM is proud to be a partner of choice for Sagar and to contribute to expanding the success of the company in sewing thread with innovative and ultra-efficient machinery and digital solutions.

For more information about SSM solutions please contact:

SSM Schärer Schweiter Mettler AG

Rütihof 8, CH-8820 Wädenswil / Switzerland

L_hc__mss--ofni, www.ssm.ch -

-

-

Becoming the Amazon of Yarns

show more show lessHow TURKTEX responds in no time to customers’ demands and offers over 1 000 different yarns.-

Fig.1: With SSM DP5-T, TURKTEX provide high quality Air Textured Yarn (ATY) -

Fig.2: Mr. Ömer Efendioğlu, plant manager at TURKTEX, is very satisfied with the great support from SSM -

Fig.3: Mr. Dündar Cetin, owner of TURKTEX, appreciates working with a company who shares the same values and is dedicated to delighting its customers

In the fast-paced market of synthetic yarns, answering the ever-increasing customers’ demands in a timely manner is a crucial competitive advantage. Since 2002, the synthetic yarn manufacturer TURKTEX has excelled at finding newer, better, and faster ways to satisfy its customers’ demands, almost in no time. With SSM DP5-T, TURKTEX takes its competitiveness and mission towards customers to the next level.

The independent Turkish textile company, TURKTEX, focuses on the world of synthetic yarns, and is a brand of Turkuaz Tekstil San. ve Tic. A.Ş. group. Founded in 2002, in Bursa, Turkey’s textile hub, TURKTEX has relied on SSM texturing machines from the very beginning, enabling the company to respond to customers’ demands with innovative, fast and flexible solutions.

Due to its superior products, TURKTEX is now Turkey’s leading company in the high value-added continuous filament sector, especially for polyester (PES) and polypropylene (PP) yarns. Its production portfolio includes yarns for home textiles (such as curtains, upholstery, mattress ticking and carpets), fashion, automotive fabrics as well as yarns for technical applications, outdoor and military. Besides supplying the local market, the company exports its products to more than 30 countries.

The largest portfolio to meet customers’ demands at any time

TURKTEX has the ambition to become the Amazon of yarns, that is the biggest synthetic yarn retailer. With a huge portfolio including polypropylene (PP) or polyester (PES) in divergent forms (recycled, flame retardant and more), various final yarn counts up to 2 000 denier, each available in 50 different colors, the company is on track to succeed.

DP5-T: the right solution to handle large assortments

In order to provide its huge range of yarns with short lead times, TURKTEX is dependent on reliable, fast, flexible and easy-to-use machines that are also quick and simple to maintain.

SSM machines have proved to be the perfect solution. In 2020, TURKTEX acquired the last SSM texturing machine DP5-T to help the company meet the demand in Air Textured Yarn (ATY) made of PES and PP (Fig. 1). It then invested in a DP5-FT false twist-texturing machine to drive business in the Drawn Texturized Yarn (DTY) market as well.

Today, the company stores approximately 1 000 different recipes in its SSM DP5-T machines and changes around every other second day the settings of the spindles. Any recipe can be removed and put back into production without any quality or repeatability issues. With its individual drive concept, the DP5-T makes it easy to switch between recipes, an indispensable feature for TURKTEX as it responds to the ever-changing needs of its markets.

TURKTEX is very satisfied with SSM’s support, service and technicians. Plant Manager, Mr. Ömer Efendioğlu (Fig 2.), highlights: "SSM cares about our needs and supports us from the first negotiation to the commissioning of the machine and beyond."

Flexibility, fast response and excellent quality

TURKTEX has a strong internal textile research and development department which ensures innovative products. To make these products a reality in the desired quality, the company can count on SSM. Mr. Dündar Cetin (Fig. 3), owner and technical director of TURKTEX, is convinced that it is crucial to satisfy customers' requirements immediately and without delay. He states: "Always keeping promises and ensuring excellent quality is possible for us, thanks to SSM DP5-T."

Flexibility is another critical factor. While standard batches in the industry are usually over 2 tons, TURKTEX handles many small orders, as low as 50 kg. Changing raw material and parameters can be laborious, but with the DP5-T, it is easy for operators to switch between orders.

In summary, Mr. Cetin says: "I am really very happy about the cooperation with SSM because we follow the same values with our identical slogan: Flexible, Fast, Safe."

For further information please contact:

SSM Schärer Schweiter Mettler AG

L_hc__mss--ofni . www.ssm.ch -

-

-

ITM 2022: Rieter Further Improves Attractiveness of Ring and Compact-Spinning System

show more show less• European roll out of precision winder NEO-YW to launch in Turkey

• Roving frame F 40 sets industry standard at 90 seconds only for doffing

• New top and bottom aprons NO-79201 offer greater durability

• i-Bearing enables 24/7 visibility for fast and smart decisions

• Berkolizer pro introduces easily adjustable UV treatment as industry-first

• Autoconer X6 is the key machine for highest efficiencyRieter is presenting the Autoconer X6 at the upcoming ITM 2022 in Istanbul (Turkey), taking place from June 14 to June 18, 2022, which further improves the attractiveness of the company’s ring and compact-spinning offering by completing the system. In addition, Rieter is showing the roving frame F 40 which doffs at 90 seconds only. SSM’s NEO-YW precision winder is launching into the European market while three key innovations in components are being introduced.

The Autoconer X6 is a globally recognized winding machine at the highest performance level, putting it on a par with all other Rieter machines. The winding machine serves as the final quality assurance in the ring and compact-spinning process and is key to the performance of the subsequent process stages.

The latest splicer generation OZ1 (Ne 20 to Ne 120 and finer) and OZ2 (Ne 3 to Ne 40) provides an optimum splice quality based on an open prism. When splicing cotton-based elastic core yarns, duo-core yarns and multi-core yarns, the open prisms are used in combination with the Elastosplicer. This has already been successfully introduced in vertically integrated mills.

The new Multilink system with Multilot offers maximum flexibility: Up to four ring spinning machines are linked to one Autoconer, with each ring spinning machine able to supply a different type of yarn.

With the integration of the Autoconer X6 into the Rieter system, the mill management system ESSENTIAL will open up over the coming years the potential for end-to-end transparency and optimization throughout all process steps.

The roving frame F 40 was already introduced to the market at ITMA 2019. A precise bobbin build-up in combination with a doffing time of 90 seconds only and the option of setting the drafting system electronically are convincing customers to invest in this machine in combination with Rieter systems.

SSM is presenting the NEO-YW precision winder which brings to bear SSM’s unmatched winding expertise into one easy-to-use and high-performing machine. NEO-YW will kick off its launch into the European market at ITM 2022.

Components for Higher Performance and Durability

The newly acquired Accotex and Temco brands are adding strength to the components family, which now includes Accotex, Bräcker, Graf, Novibra, SSM, Suessen and Temco. Rieter is presenting three key innovations at ITM.

Accotex’s new top and bottom aprons NO-79201 offer outstanding tear and abrasion resistance and superior friction properties. They can be applied universally, making service and stocking more efficient.

Temco’s intelligent bearing solution i-Bearing for filament machines allows condition monitoring online. By identifying critical conditions, bearings can be replaced before they fail which helps to minimize machine downtimes.

Today, Bräcker’s berkolizing technology of treating rubber cots with UV light to improve the surface has become an industry standard. At ITM, Bräcker is introducing the berkolizer pro which stands for consistent, energy-efficient, and adjustable UV treatment.

Opportunities and Challenges to the Spinning Industry

2021 was an unprecedented year for the global spinning industry. Driven by the market recovery after the pandemic and the regional shift of the industry, customers invested in new spinning systems at levels never experienced before. And despite the current uncertainties, customers continue to invest.

As market and technology leader, Rieter succeeded in this environment in posting a record order intake for 2021. This is clear evidence of the high level of trust customers have in Rieter. Dr. Norbert Klapper, CEO of Rieter, says: “Systems, machines, components, parts and services from Rieter have ensured competitiveness and success for customers over many years in the past and will continue to do so in the future.”

Dr. Klapper also comments on the challenges that lie ahead for the industry as it takes advantage of market opportunities: “The pandemic is not over yet, and business is exposed to dramatic cost increases as well as shortages in material supplies and logistics. In difficult times, it is important to work together even more closely than under normal circumstances. It’s all about true partnership and trust – the basis of Rieter’s business for 226 years.”

Visit Rieter at ITM 2022 at TÜYAP Fair Convention and Congress Center, Istanbul, Turkey, from June 14 to 18, 2022 in hall 3-314 at booth C07. Register to experience our virtual booth from anywhere, anytime via [www.rieter.com/company/virtualworld] with the ITM 2022 edition going live June 10, 2022.

-

-

Digital potentiometer

show more show lessSSM has launched the digital potentiometer for most of its existing machines to create a strong foundation for a consistent bobbin quality and reduce maintenance work. The retrofit on the machine can easily be done on single spindles. A section can therefore contain different potentiometers from different generations. Some older machines will require a software update.Customer benefit

Seize the opportunity to exchange your analogue potentiometer with a digital one and profit from various advantages. The new potentiometer enables 400 times more measuring cycles than the analogue potentiometer. Additonally, an important improvement is a more accurate and stable signal with an exact resolution and no drift. Further, there is also no wear and tear side effect for this spare part.

All customers with machines as mentioned on the flyer, no matter which PCB, can profit from this new retrofit kit.

Download the "Retrofit Digital Potentiometer" flyer HERE and ask our service support for an offer.

Please do not hesitate to contact us for further information about SSM service solutions at L_hc__mss--troppus

SSM Schärer Schweiter Mettler AG

-

-

Conversion traverse unit TW1/2

show more show lessAll customers with TW1/TW2 machines get the chance to upgrade their TW1/2 machines with a new traverse unit kit. The conversion requires the customer to replace the existing traverse units with TW2plus. This upgrade enables the customers to maintain the performance of their TW1 and TW2 machines at a high level over the whole lifetime.The main advantage of this retrofit for the customer lies with faster and more powerful motors. Due to stronger motors the speed can be increased, default rate can be decreased and lifetime of motors is longer. All factors have a very positive impact on productivity, which is a key criteria for production.

Download the "Conversion Traverse Unit TW1/2" flyer HERE and ask our service support for an offer.

Please do not hesitate to contact us for further information about SSM service solutions at L_hc__mss--troppus

SSM Schärer Schweiter Mettler AG

-

-

More accurate length measuring on PW machines

show more show lessSSM has launched a new support-roller sensor for cylindrical tubes to significantly reduce the variation in length measuring. Accuracy of up to +/- 0.3% can be achieved with the new kit consisting of software and mechanical parts. The retrofit on the machine can easily be done on single spindles.Customer benefit

Customers with PW1/2/3/8/X machines and cylindrical tubes profit from clear advantages in length measuring. Already when re-/winding 5000m of yarn the improved accuracy on length can be felt.

Further, there is less waste in the downstream process which results in a higher profitability for the customer. SSM already offers this option for other machines with great success and is pleased to make one of the latest length measuring technologies available to its customers.Once customers decide to upgrade their machines, they will benefit from improved accuracy and save money due to less waste.

Additional spare parts

All customers with PW machines, which are equipped with a Multiflex, Smartflex or a Precicontrol PCB can profit from this new kit. The following spare parts are required to improve the length measuring substantially: magnetic sensor, aluminium support, support roller with magnet ring, rubber-seal, software.

Download the "Support Roller Sensor PW" flyer HERE and ask our service support for an offer.

Please do not hesitate to contact us for further information about SSM service solutions at L_hc__mss--troppus

SSM Schärer Schweiter Mettler AG

-

-

Extend machine lifetime for 10 years

show more show lessRetrofits are often very popular and worthwhile, if they enhance the lifetime of a machine. All customers who have a PW1, PS6 or PS6plus and decide to change their spindle control unit can upgrade from Precicontrol or preciflex™ to Smartflex.A big advantage of Smartflex is that the control unit does not require any backup batteries and is therefore more stable than Precicontrol or preciflex™. Upgrading electronics of the machine can prolong its usability for additional 10 years.

With a Smartflex upgrade, SSM customers have clear advantages. Not only can they continue to use well maintained machines for another 10 years, but they also save money and add their share to a sustainable environment for consumers. Additionally, the new system is more stable which facilitates handling and maintenance. Latest version of machine terminal with coloured display and state-of-the-art electronical control board results in a significant improvement of the system communication, less break downs and higher machine efficiency.

Download the "Retrofit to Smartflex" flyer HERE and ask our service support for an offer.

Please do not hesitate to contact us for further information about SSM service solutions at L_hc__mss--troppus

SSM Schärer Schweiter Mettler AG

-

-

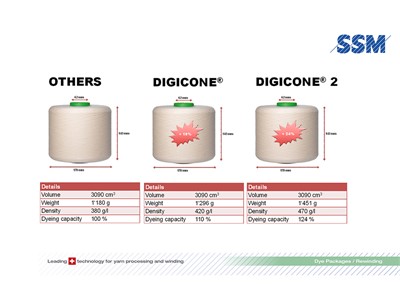

DIGICONE®2 – SSM generates the “perfect” yarn package

show more show lessSSM software manager Göksel Karaarslan knows only too well how a properly wound package looks like: it features a uniform density and no visible surface structures. “No pattern”, as the experts say. This is important because a yarn package can, for example, only absorb the colour evenly if it is neatly wound. “Nobody wants to wear spot-tily dyed clothes”, says Karaarslan. More-over, it is much easier to efficiently process sound packages.The variety of yarns and packages – a particular challenge

The problem is: the winding machines often fail to instantly wind packages that can be easily dyed. This is due to the fact that there are thick yarns, thin yarns, rough yarns, smooth yarns, straight packages, conical packages … the list could be continued infinitely. Good winding machines must take into account all these parameters and, at the same time, constantly produce packages of high quality. In case a package is wound in a suboptimal way, this situation will lead to problems in the downstream processes and, as a consequence, result in additional disadvantages. Additional disadvantages, however, cost time and money – money that is often lacking in the highly competitive textile market. Therefore SSM has developed an algorithm, in cooperation with a renowned university, enabling the winding machines to wind the “perfect” package, regardless of the yarn.

Images instead of laboratory tests

The engineers and mathematicians opted for a special approach. Instead of measuring parameters such as yarn tension, density, material, or yarn diameter, and packing them in complicated formulas, they translated the SSM expert knowledge into a theory, allowing for a precise prediction of package structures and density distribution. Using methods from the number theory, they finally managed to get a grip on the “chaotic and dynamic system” of package winding.

Based on the calculations, it was possible to devise the DIGICONE®2 algorithm that can be directly implemented into the winding machine control software. By means of high-speed recordings during the winding process and with the aid of x-ray computed tomography, the success of the SSM project was finally confirmed (see image comparative spool). Result: the identically constructed machines, which previously were not always able to wind a package that can be easily dyed, accomplished this task straight-away with the new software.

Competitive advantage through innovation

Thanks to the cooperation between SSM and university, the idea could be optimally implemented. “The innovative DIGICONE®2 algorithm enables us to stand our ground in the competition with other winding machine manufacturers”, says Karaarslan. The algorithm is successfully used by the latest SSM machine generation, and many customers have already tangibly profited from it.

For more information about SSM applications please contact:

SSM Schärer Schweiter Mettler AG

Neugasse 10, CH-8810 Horgen / Switzerland

L_hc__mss--ofni, www.ssm.ch

-

-

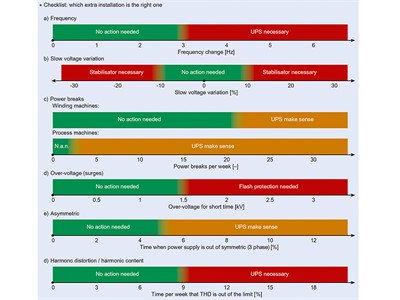

Electricity supply for SSM machines

show more show lessJust like all modern textile machines SSM machines rely on a stable electricity supply to function correctly. A stable supply also extends the lifetime of the electronic boards and makes the machine more efficiently.What’s a stable electricity supply?

An electricity supply is characterized by frequency, magnitude, waveform and symmetry of the three-phase-voltages. If the following disturbances exceed certain limits then the quality will be affected:

• main power shortages

• jitter light

• voltage variations

• frequency variations

• slow and rapid voltage changes (over-voltage, spikes)

• unbalance of three phase voltage

• harmonic distortion

An exact definition of a stable supply is given in the European Norm (ex. EN50160). SSM assures its machine function correctly if the norm is fulfilled.

How to test the electricity supply

To test if a supply is inside the norm you have to analyse your net over a long time. Variations over the seasons have to be taken into consideration (summer/winter influences etc.). Often a weekly analyse will give you sufficient information about your net. SSM can offer a short analyse of your net. Very often though consumers know their supply. Important are the amount of main power shortages and voltage variations.

How to connect the machine to the supply

A lot of errors can be avoided by connecting a machine correctly:

• Is the grounding system of the machine correct?

• Sufficient cross section of the supply pipe?

• Avoid connecting machines of different power classes to the same main distributor.

How to protect a machine

There are a number of devices that can help to protect a machine, e.g. UPS (unbreakable power interrupt), power stabiliser, flash protector, or net filter. It is important to choose the best and most economical solution. The beside checklist will help you to choose appropriate equipment.

-

-

SSM DIGICONE® 2 -Advanced winding algorithm

show more show lessDIGICONE® step precision winding – developed by Schweiter in the 1970s – combines the advantages of random winding and precision winding.The ratio between double strokes and number of revolutions is kept constant for a certain diameter range. The crossing angle varies only slightly within a range of ±1°. This results in an enhanced package density that does not change with increasing package diameter. So the building of pattern zones is avoided and the package maintains a stable structure without any ribbons. Due to this stable structure, the risk of complete layers “slipping off” during the unwinding process of dyed packages, as known with random winding, is completely eliminated.

The introduction of the XENO platform opened new possibilities for optimizing the winding algorithm. Thanks to this new machine platform, SSM could release DIGICONE® 2, enabling an increase of dye package density by another 10–24% with unchanged dyeing recipes.

For more information about SSM solutions please contact:

SSM Schärer Schweiter Mettler AG

Neugasse 10, CH-8810 Horgen / Switzerland

L_hc__mss--ofni, www.ssm.ch

-

SSM - Leading Swiss technology for yarn processing and winding

SSM - Leading Swiss technology for yarn processing and winding